In today’s tight labor market, hiring warehouse workers has become a difficult and costly process. At the same time, manual fulfillment processes are slow and inefficient and forklifts can pose significant injury and inventory damage risks.

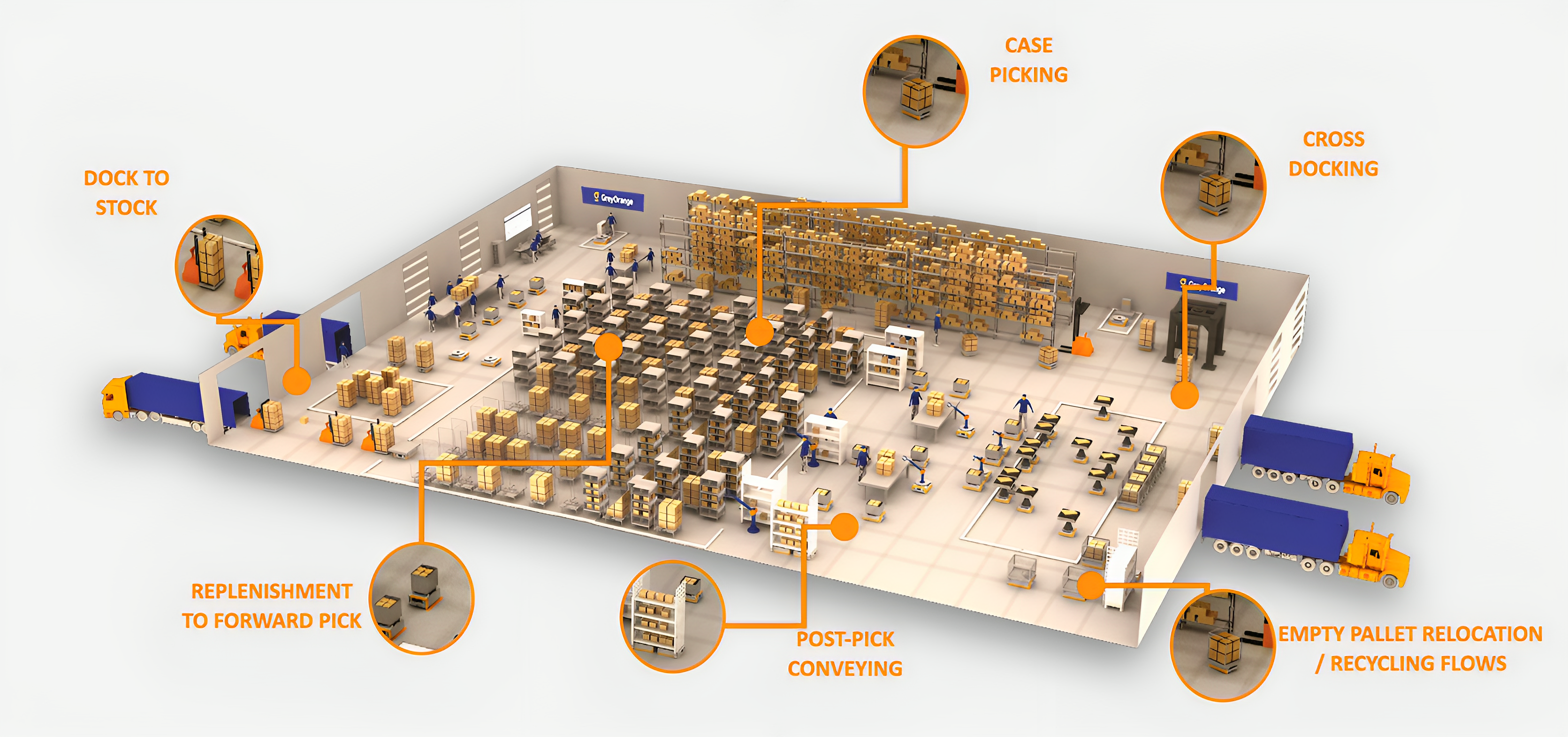

To address these challenges, GreyOrange offers an Intralogistics solution that can automate labor-intensive workflows related to material and pallet movement in your warehouse. The Ranger Intralogistics robot (RIL), powered by GreyMatter multiagent orchestration, is a highly adaptive autonomous mobile robot (AMR).

Application Guide | Spec Sheet | Case Study

by 50-60%

2x faster

8-12 weeks

6-18 months

Customer Success: Sodimac optimizes material movement with the world’s largest pallet-moving AMR installation

1M sq.ft. facility in Chile servicing a chain of home improvement stores, receiving 4,000 single SKU pallets and dispatching 4,000 mixed SKU pallets per day

| Dimensions | 1280 x 920 x 350 mm | 51.2 x 36.2 x 13.8 in. |

|---|---|---|

| Max Payload | 1000 kg | 2204 lbs. |

| Max Speed | 2 m/s | 4.5 mph |

| Payload Type | Closed pallets, open pallets, pallet boxes, gaylords, moveable racks, trolleys | |

| Dimensions | 1600 x 900 x 2100 mm | 63 x 35.4 x 82.7 in. |

|---|---|---|

| Max Speed | 1.50 m/s | 3.4 mph |

| Max Payload | 1400 kgs | 3080 lbs |

| Payload Type | Closed pallets (from an elevated pick up), open pallets (from ground), pallet boxes, gaylords, moveable racks, trolleys | |