More than 16% of $4.583 trillion of U.S. retail sales were returned in 2021. And the return rate for online sales (23% of total sales) was even higher: 20.8%.

Nobody wants merchandise returns. But the key to protecting margins is handling them more effectively to minimize sale losses and write-offs. All through a fully automated return process that increases merchandise exchanges and resales by enhancing the visibility, flow and accessibility of return inventory.

Ensure returns preference for order picking by maintaining returned merchandise as separate virtual inventory, eliminating need to demarcate separate physical inventory storage. Prioritize returned inventory that passes through QC and VAS for outbound order picking using configurable storage and system-directed picking.

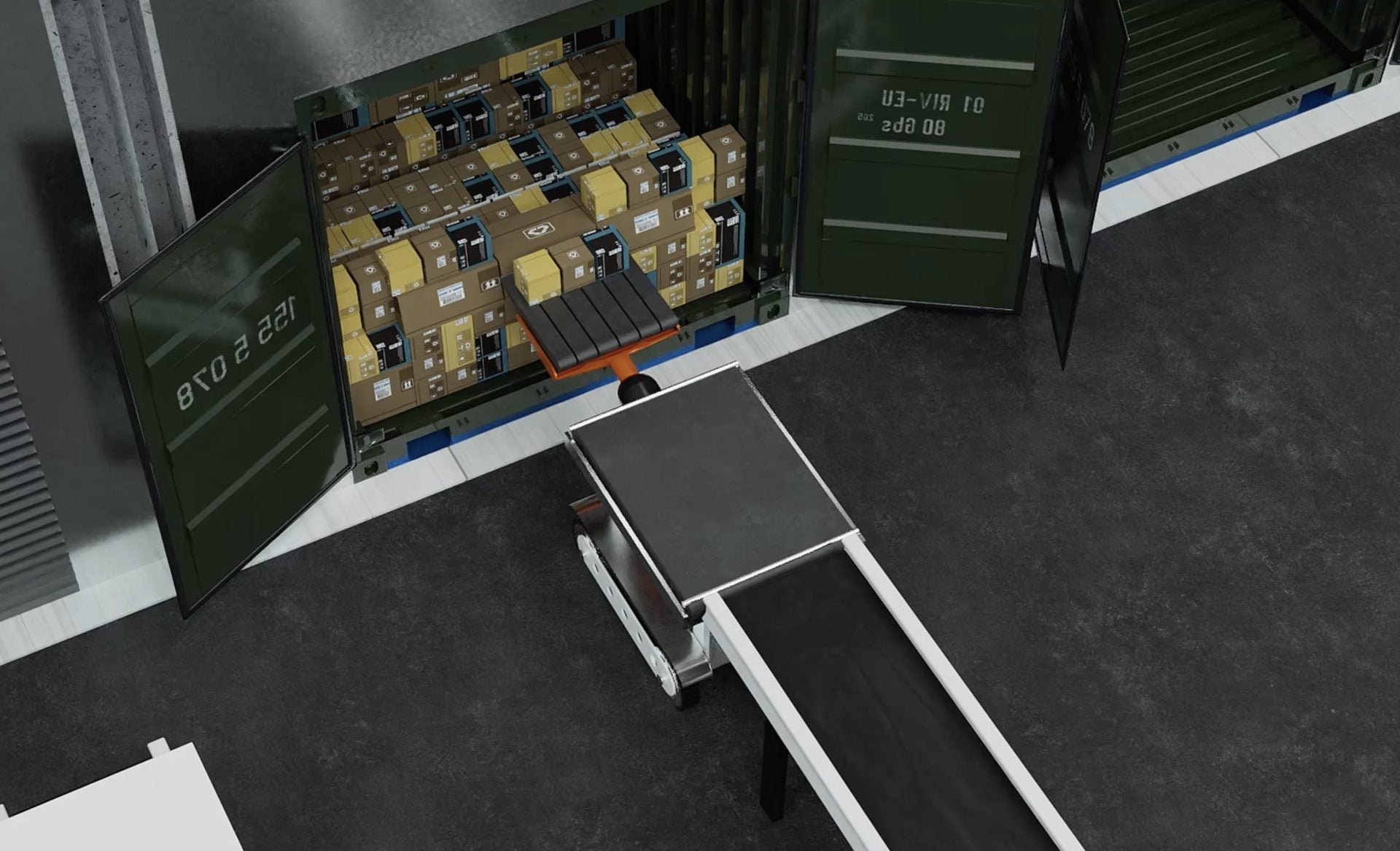

Enhance end-to-end movement of returned inventory with a smart conveying solution that moves inventory where it needs to be – whether for liquidation, quality check, value-added services, putaway or cross-dock. Or deploy multiple workflows to move inventory to a forward – manual and automated, or cross-dock area – to combine with partially picked orders in accordance with SLAs.

Manage multiple returned SKUs in the same location to facilitate efficient space utilization in active inventory. Execute putaway into pre-allocated locations to achieve quicker restocking and better space utilization.

Enhance processing – from through sortation and consolidation – to achieve higher efficiency and faster SKU restocking.

Improve customer satisfaction scores by over 93%, through richer automation that enhances return processing. “Save sales” by broadening visibility of warehouse inventory – capitalizing on return data showing 42% of items can be exchanged if correct items are available.

An optimized returns process delivers an automated, efficient dock-to-stock – or cross-dock – operation to improve restocking, prioritize exchange and resales of returned items, and ease picking and labor needs. All to maximize sales – and enhance ROI.