Warehouses face relentless pressure to increase efficiency, yet case picking — a critical yet often overlooked process — remains a significant bottleneck. This labor-intensive task slows fulfillment and increases costs, compounded by the growing challenge of finding and retaining skilled forklift operators due to training and certification demands.

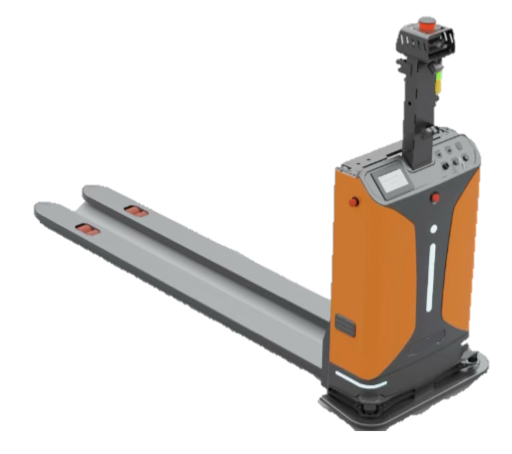

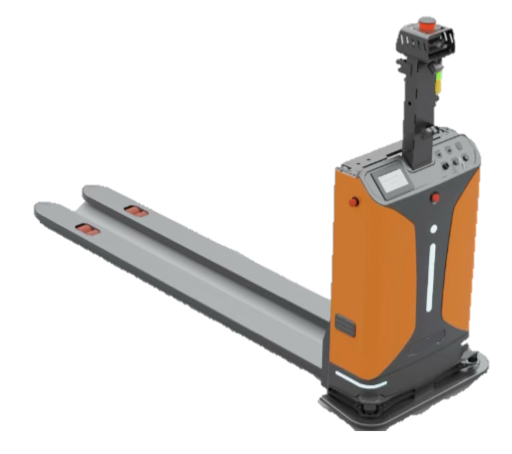

GreyOrange addresses these challenges with intelligent cobots designed to automate and optimize case picking. Our solutions include:

This adaptable setup enhances productivity and efficiency across industries, empowering warehouses to meet their unique operational needs and stay competitive.

Food and Beverage Distribution Food and Beverage Distribution |  Consumer Goods Consumer Goods |  Big Box Store Suppliers Big Box Store Suppliers |  Grocery Grocery |  Pharmaceuticals and Healthcare Pharmaceuticals and Healthcare |

Runs on a wearable device, keeping operators informed of the next pick task and location

Are based on fluctuating order volumes, seasonal demands and changing operational conditions

Ensures that item stacking improves space utilization and eliminates inventory damage

Enables bots to operate in narrow aisles and handle multiple pallets/trolleys simultaneously

Determines best storage location for each inventory item based on a self-learning model

Helps manage increased peak volumes better without increasing robots

by up to 300%

by 50%

6-12 months

6-12 months

Integrate with Ease: Work seamlessly alongside existing systems, other robots, human workers, and infrastructure for smooth coordination and optimized workflows.

Empty pallet stacking/de-stacking machine |  Shrink wrapping machine |  Conveyor transfer system (powered/gravity-based) |  Pallet-lifting system |