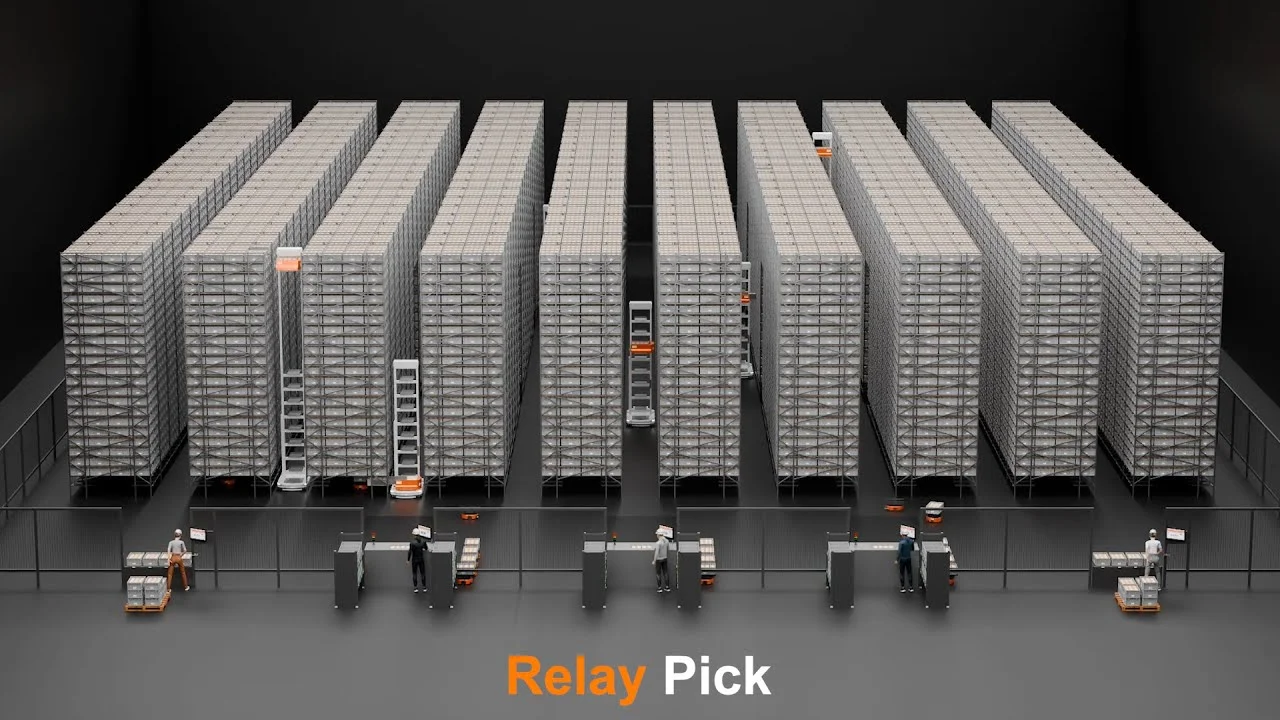

Taking vertical space utilization up a notch

So many SKUs to store, so little space. It’s a problem getting more difficult – and more expensive – by the day.

That’s why many retailers and 3PLs are maximizing per-square-foot utilization by leveraging vertical storage space and increasing throughput from the forward-picking zone.

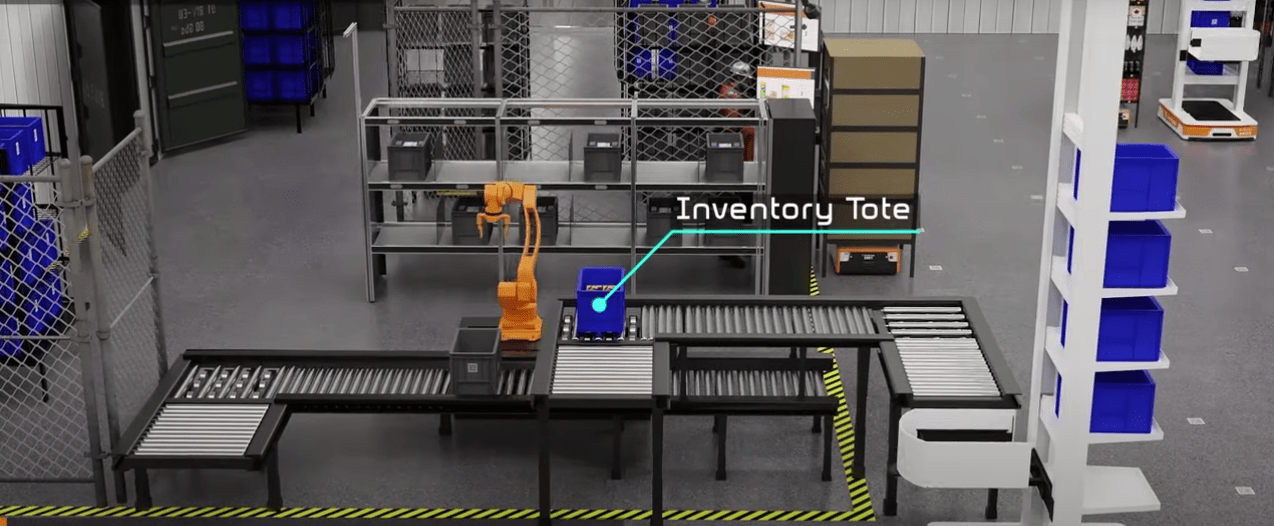

GreyOrange Tote-to-Person (TTP) solutions provide the flexibility and vendor-agnostic foundation necessary to create truly omnichannel, agile fulfillment centers. Through the combination of tote/carton handling applications with real-time adaptability to dynamic channel and SKU popularity, warehouses and distribution centers (DCs) are able to:

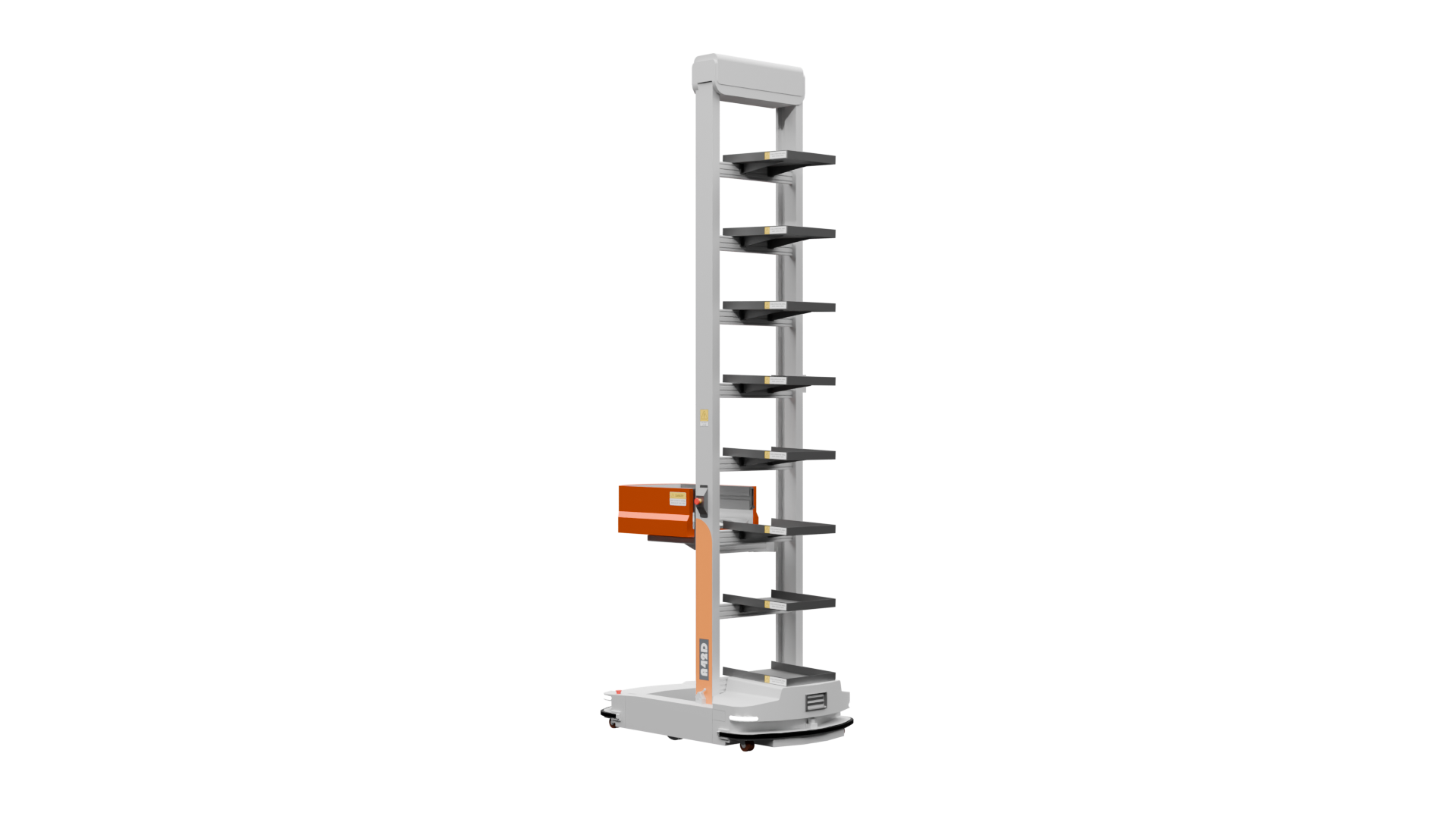

- Maximize vertical space utilization and storage density

- Easily scale up or down for changes in throughput or footprint

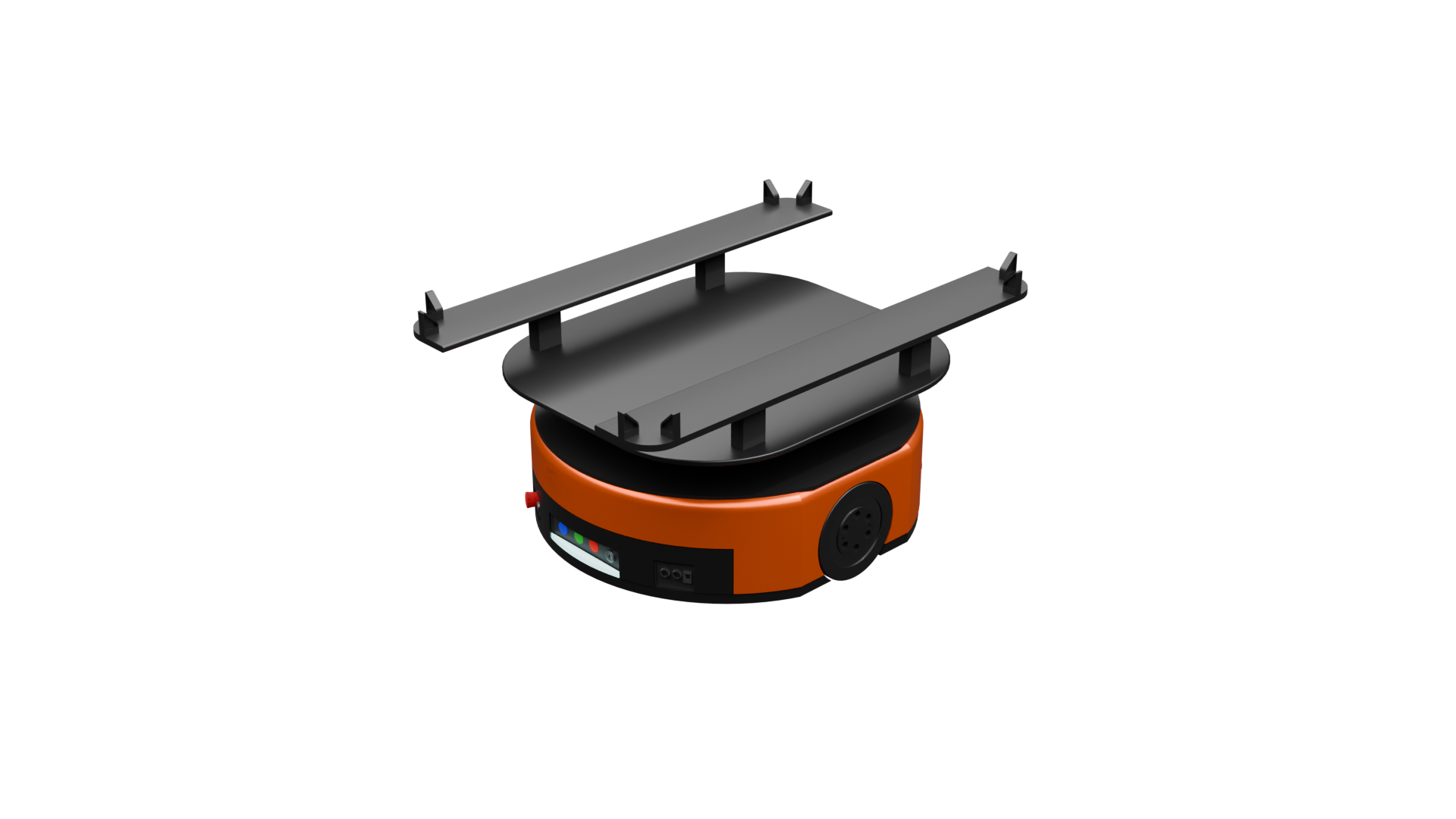

- Simultaneously use vertical tote mover (VTM) and horizontal tote mover (HTM) robots for increased performance and speed

- Accommodate oversized inventory in a hybrid storage system